Understand the needs

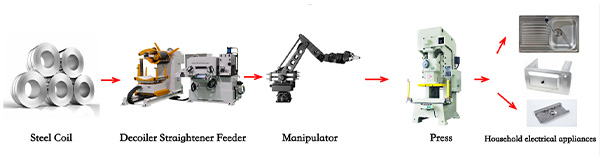

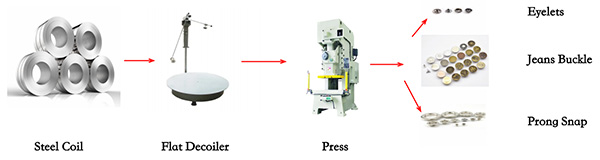

Understanding their specific needs and requirements, we formulate solutions and product solutions for different production lines.

Normally, steel process is faced with numerous challenges during factory daily operations. One of their top concerns is the safety of their employees when working with heavy equipment and in hazardous environments. They must ensure that all necessary safety measures are in place and that employees are well-trained to operate the equipment safely.通常,钢铁工艺在工厂日常运营中面临着许多挑战。他们最关心的问题之一是员工在使用重型设备和危险环境中工作时的安全。他们必须确保所有必要的安全措施到位,员工接受过安全操作设备的良好培训。通常,钢铁工艺在工厂日常运营中面临着许多挑战。他们最关心的问题之一是员工在使用重型设备和危险环境中工作时的安全。他们必须确保所有必要的安全措施到位,员工接受过安全操作设备的良好培训。Usually, gabion machines face many challenges in the daily operation of factories. One of their biggest concerns is the safety of employees when working in heavy equipment and hazardous environments. They must ensure that all necessary safety measures are in place and that employees have received good training in safe operation of equipment.通常,石笼机在工厂的日常运营中面临着许多挑战。他们最大的担忧之一是员工在重型设备和危险环境中工作时的安全。他们必须确保所有必需的安全措施已备妥,而雇员亦已接受有关安全操作设备的良好训练。Usually, gabion machines face many challenges in the daily operation of factories. One of their biggest concerns is the safety of employees working in heavy equipment and hazardous environments. They must ensure that all necessary safety measures are in place, and employees have received good training on safe operation equipment.

Additionally, steel mills are constantly seeking ways to cut costs without sacrificing quality or safety. They explore various cost-saving strategies, such as optimizing energy usage, reducing waste, and minimizing downtime.此外,钢铁米尔斯不断寻求在不牺牲质量或安全的情况下削减成本的方法。他们探索各种节省成本的策略,例如优化能源使用,减少浪费和最大限度地减少停机时间。此外,钢铁米尔斯不断寻求在不牺牲质量或安全的情况下削减成本的方法。他们探索各种节省成本的策略,例如优化能源使用,减少浪费和最大限度地减少停机时间。At the same time, Candid has been committed to improving the safety of equipment operation and future sustainable developmentMeanwhile, Candid has been committed to improving the safety of equipment operation and future sustainable development

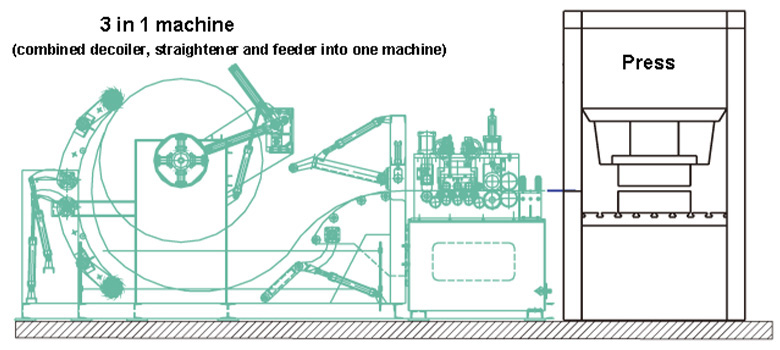

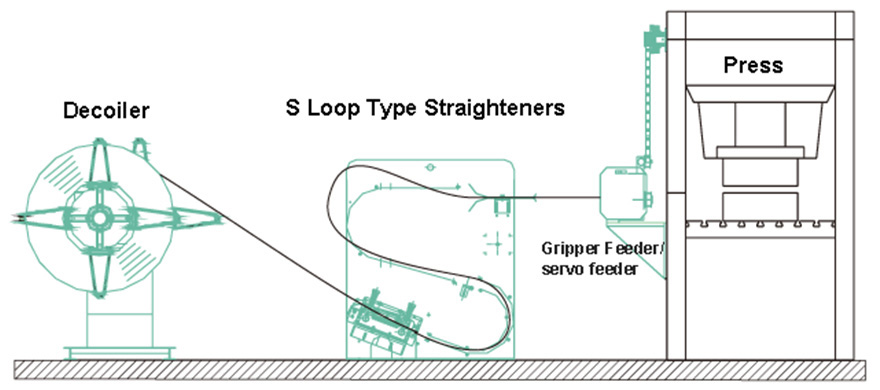

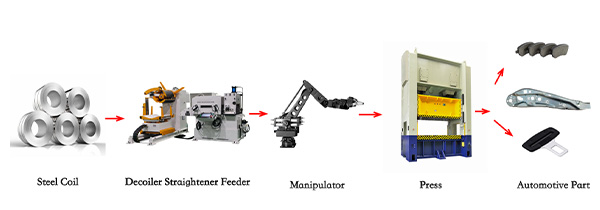

Another challenge is to improve production efficiency while maintaining high-quality standards. This requires streamlining processes and adopting new technologies to enhance productivity. Finally, steel mills must provide customized solutions to meet the unique needs of their clients. This may involve adapting their production processes to meet specific product requirements or collaborating with clients to develop tailored solutions.另一个挑战是在保持高质量标准的同时提高生产效率。这需要简化流程和采用新技术来提高生产力。最后,米尔斯必须提供定制的解决方案,以满足客户的独特需求。这可能涉及调整其生产流程以满足特定的产品要求,或与客户合作开发定制的解决方案。另一个挑战是在保持高质量标准的同时提高生产效率。这需要简化流程和采用新技术来提高生产力。最后,米尔斯必须提供定制的解决方案,以满足客户的独特需求。这可能涉及调整其生产流程以满足特定的产品要求,或与客户合作开发定制的解决方案。Another challenge is to improve production efficiency while maintaining high quality standards. This requires simplifying processes and adopting new technologies to improve productivity. Finally, CANDID must provide customized solutions to meet the unique needs of customers. This may involve adjusting its production process to meet specific product requirements, or collaborating with customers to develop customized solutions.

Understanding their specific needs and requirements, we formulate solutions and product solutions for different production lines.

We provide cutting-edge equipment and technology that prioritizes safety, efficiency and cost savings.

By implementing these solutions, the Gabion Machine factory can optimize production processes, reduce waste, and improve overall efficiency.

We also offer a range of product solutions tailored to meet specific customer needs.